Monday, February 2, 2015

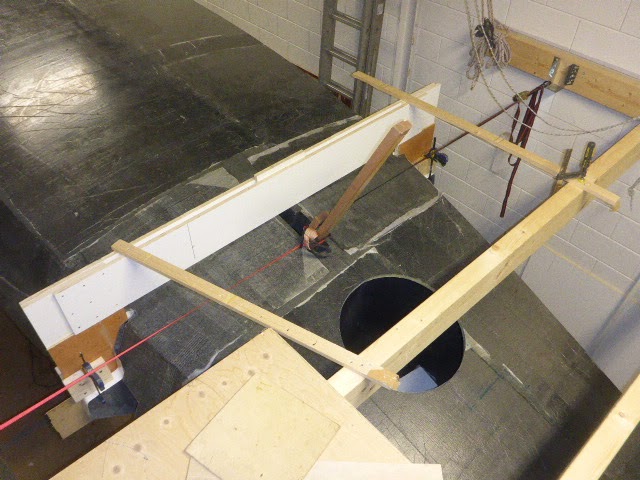

cutting some holes in the back

Today I was to tired from yesterday to laminated the back of the front beam bulkhead so I did keep it simple to laminate a carbon chain plate for my friend Rob and fill the edges between the deck on the beam mounts. I did also take away the molds under the the beam mounts, it was a nice release. This was relative simple job and I had enough time left so I started to measure the hole for after beam mounts, this was more simple than the front and quick done. The next thing was to cut the hole in the back. It is now ready for Friday when Rob comes by to help outline the after beam mounts.

Sunday, February 1, 2015

many pieces of UD carbon

We spend the whole morning with cutting the UD pieces and in the afternoon we started with laminating the front side of the beam bulkhead with many UD pieces it where eleven steps what had to be done. Yesterday I thought we maybe can do the backside also, but this did take a long time and it was almost 20.00 before we were home. Tomorrow I am free in the afternoon so can can do some smaller jobs.

Saturday, January 31, 2015

extra layers carbon on the front beam bulkhead

Yesterday I had to work so I could not do much so I only did do some putty in the corners and some small tapes so I could do the extra layers carbon what are decrypted for this bulkhead. I only did the front side because I was on my own and it take some time to prepare both sides. I will do the other side tomorrow, the UD what I did on the front I did already on the back.

Sunday, January 25, 2015

a long productive day

I started in the morning to do the other side of the bracket mold and I corrected the other side were I forgot do the upper part with carbon only three layers and it gives some extra strength. In the afternoon I spend the most of the time under the cockpit floor to tape the cockpit deck on the underside. Fetske laminated the carbon and did the mixing and gave it to me so I could stay below. It was 19.30 when we did go home.

Saturday, January 24, 2015

fit the lower folding strut bracket mold in place

I first started to demount the spacer between the beam mounts and to grind so putty away to get some clean edges. Next thing was to make lower folding strut bracket mold fit, this did take some time. The molds are screwed to the brackets after they were waxed. As last I laminated only one side because it was then already 17.30. I was finished at 18.45

I first started to demount the spacer between the beam mounts and to grind so putty away to get some clean edges. Next thing was to make lower folding strut bracket mold fit, this did take some time. The molds are screwed to the brackets after they were waxed. As last I laminated only one side because it was then already 17.30. I was finished at 18.45Friday, January 23, 2015

glued the front beam mounts in place

Rob did came today to help to put the boat exact level and to put the beam mounts in place. It was very handy to have some extra hands and technical skills. I glued them in place on my own because Rob is allergic to epoxy he did get this wen he build his own boat.

Sunday, January 18, 2015

tapped the cockpit floor

We tapped the topside of the cockpit floor, the underside still have to be done, maybe next week.

The barn was kind of a mess so we cleaned the floor and stocked the battens on the top shelf so we have some more walking space around the boat.

The barn was kind of a mess so we cleaned the floor and stocked the battens on the top shelf so we have some more walking space around the boat.

Subscribe to:

Posts (Atom)